Facilities

Overview

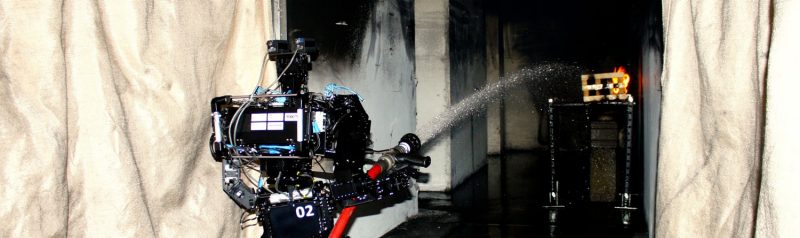

We maintain two laboratories to evaluate the behavior of systems and materials when exposed to extreme environments. Our research has developed custom advanced measurement and imaging systems including fused thermography - digital image correlation (TDIC), full-field high resolution heat transfer to surfaces, photogrammetry fused with thermography and surface heat transfer, multi-modality vision systems for imaging and object classification in harsh environments

Our on-campus laboratory in Goodwin Hall:

- small-scale experiments (less than 1 m).

- 1,000 ft2 laboratory for material characterization and assessment.

Our off-campus laboratory at the Prices Fork Research Center:

- large-scale experiments (up to 5 m) with higher exposure environments.

- 1,100 ft2 laboratory with 5,000 cfm hood capable of handling fires up to 500 kW.

Capabilities

- Carl Zeiss AxioVert A1 Inverted Microscope for microstructure investigation of heat damaged materials including metals, composites, and other tested materials with magnification up to 1000X and software for automatic determination of material features including grain size, phase content, and porosity

- Sample Preparation Equipment using state-of-the-art sectioning, mounting, polishing, and etching specimens for optical evaluation

- Environmental Chamber for durability of robotic platforms in high temperature / high humidity conditions as well as accelerated aging of materials

- 150 kN Instron Mechanical Testing Machine with tension/compression/bending loading capabilities with induction heating for controlled temperature rise and corrosion cell for accelerated aging of samples

- Netzsch STA 449F1 Jupiter Simultaneous Thermal Analyzer (STA) including TGA for gravimetric response as well as DSC to measure specific heat and decomposition properties

- Micro-Combustion Calorimeter (MCC) to measure heat release rate versus temperature and effective heat of combustion on milligram samples

- Cone Calorimeter for thermal response, ignition, and burning of 4 in. x 4in. coupon samples, heat flux up to 80 kW/m2

- Quartz Faced Heater Panel System measuring 3 ft x 2ft quartz faced heater panels for radiant heat flux to 60 kW/m2

- Large-Scale Hood Calorimeter to measure heat release rate of fires up to 500 kW

- High Temperature Wind Tunnel for wildland fire testing of construction, vegetation, and firebrands

- Firebrand Generator to assess the ignition of building construction by wildland fires

- Jet Fire Exposures for fire resistance testing

- Thermography / Digital Image Correlation (TDIC) system for small to large scale deflection and thermal imaging using a Correlated Solutions VIC3D DIC system and three SC655 thermal imaging cameras with calibration range up to 2000oC

- Full-field Heat Flux Measurement using thermography and inverse heat transfer

- Photogrammetry System for real-time 3D reconstruction of objects with ability to overlay measured temperature and heat flux onto surfaces

- Lightweight Thermography using FLIR A35 cameras for space and weight restrictive applications

- Hokuyo LIDAR systems for two and three dimensional mapping